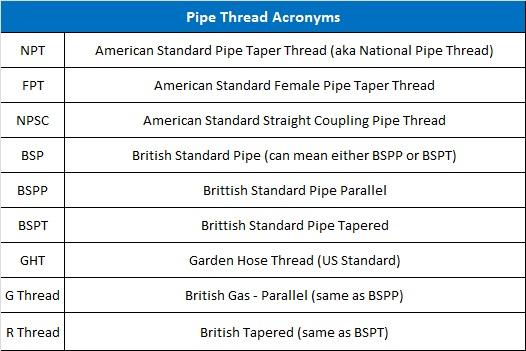

Before we start discussing the most common solenoid valve threads, here is a link to the NPT, BSP, GHT specification tables below. And here is a link to the pipe thread acronyms.

Solenoid Valve Port Options:

Solenoid valves can come with either inside or outside threaded ports. In addition to threaded ports, valves are also available with barbed ports (usually only in sizes less than 5/8″ ID (inside diameter) hose and plastic valve bodies). Below, you will find a table containing the most common acronyms used for solenoid valve threads. As you can see, multiple standards are used for solenoid valve threads. The next section will discuss the interchangeability issues between these standards.

US Standard (NPT) vs. British Standard (BSP):

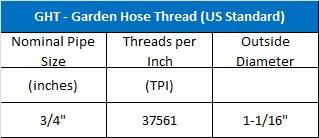

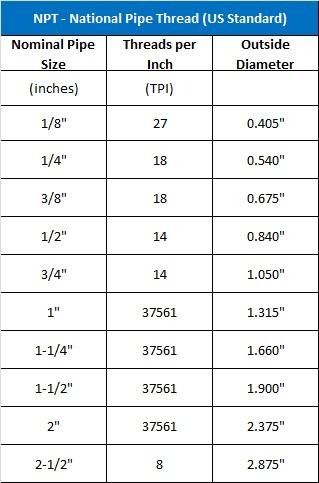

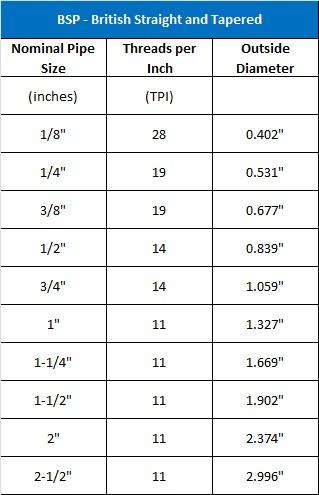

Wouldn’t it be too easy if there was only one pipe thread standard in the world! The tables below show the threads per inch (TPI) values for both the NPT and BSP standard threads. They also show the outside or major diameter for both standards. As you compare the two, you will notice that the outside diameters are very close. In fact, they are so close that in most cases the difference would go completely unoticable. However, the larger problem resides in the thread per inch values.

After closer examination of the two tables, you may come to the conclusion that at least the 1/2″ and 3/4″ sizes are interchangable. The answer is yes and no. There are actually a lot more to to threads than the tables let you believe: The angle of the thread can also be different between different standards. The BSP thread uses a 55 degree thread angle while the NPT standard uses a 60 degree thread angle.

Now you may ask, “is this the end of the line? Can’t a BSP thread ever be used with an NPT counterpart?” The only time this is possible (from my experience) when you use a 1/2″ or 3/4″ straight male thread with the a straight thread fitting that uses a gasket or a cone seal. In this case, you are not trying to have the two threads (female and male) make the seal. Instead, the seal will be created by the gasket or cone seal. The 1/2″ and 3/4″ NPT and BSP are close enough, so they can certainly be used as fastening threads (i.e. to compress the soft sealing material against the end of the solenoid valve port).

Parallel (a.k.a. Straight) vs. Tapered Thread:

Tapered pipe threads are self-sealing. For that reason they are called “joining threads.” The best seal is accomplished by using a tapered external thread with a tapered internal thread. You can certainly use a tapered external thread with a parallel internal thread but the seal will not be as good since the tapered external thread will not screw as deep into the non-tapered internal thread.

The most common NPT thread is tapered (both internal and external). NPSC (American Standard Straight Coupling Pipe Thread) is an example of a non-tapered thread. Otherwise, the NPSC has the same thread form as the NPT.

The BSP (British Standard Pipe Thread) threads are available in tapered and non-tapered forms. What ever threads you are using, you will need to remember the following when working with solenoid valve threads:

- Parallel internal and external threads are Fastening Threads and require the use of a gasket or cone seal.

- Tapered threads are Joining Threads and create a pressure tight seal when used with jointing compound or Teflon tape.

![Read more about the article Piping component standard ASME B-16 [QC-Notes]](https://englogs.com/wp-content/uploads/2022/06/QC-Notes-Piping-component-standard-1-300x179.jpg)