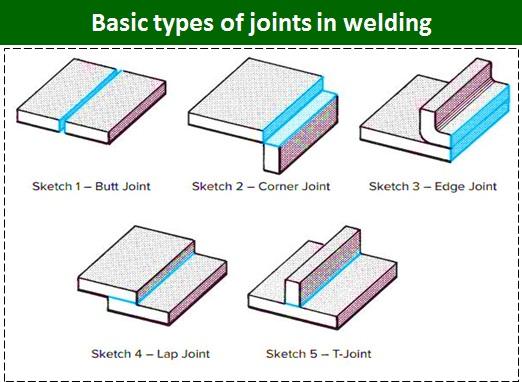

Basic types of Joints in Welding

There are only five basic types of joints in welding, the most common weld joints will be described in terms of their uses, advantages and disadvantages, joint preparation, and economy.

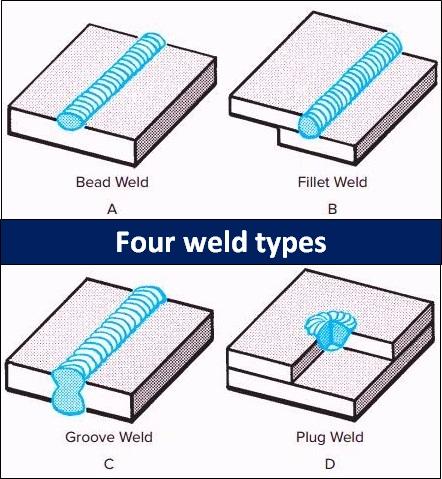

Four Weld Types:

It is important to understand the four basic weld types. They are bead (surface) weld, fillet weld, groove weld, and plug (slot) weld. All four are shown in

Bead welds These welds, also called surface welds, weld single-pass deposits of metal, as illustrated in bead welds, are used to fabricate metal pads and replace metal on poor surfaces.

Fillet weld in weld consists of one or more beads deposited at right angles formed by two plates,

They are used for lap joints and T joints. Fillet welds take up a triangular cross-section due to the space placed at the weld joint. The weld symbol used for fillet welds takes on the same triangular shape as the weld, so it can be easily identified. Open corner joints are also welded with fillet welds. It is important to understand the terminology applied to fillet welds. The different parts of a fillet weld. an important aspect.

A weld has its profile. The weld face can be convex:

concave, or flat. This aspect is important when determining the size of fillet welds, which will be covered later.

in this chapter.

Groove welds These welds consist of one or more beads that are deposited into a groove, groove welds are used for butt joints. The butt joint may be left unprepared with square edges, or it may be prepared with a bevel or J-groove. If the two members are beveled or J-grooved when brought together, they take the shape of a V or U and thus these grooves are referred to at the butt joint—that is, a V-groove or A.

U-groove butt joint. This weld applies to both plate and pipe:

Plug welds These welds, which are similar to slot welds, are used to fill slotted or circular holes in lap joints; if the hole, or slot, is large, a fillet weld is created around the facing face of the joint. can go. Figure 4-5 shows an example of a hole with a spot weld, a plug weld, and a fillet weld in it. The plug weld may or may not completely fill the joint.

![Read more about the article Gas welding machine parts and functions [oxy-acetylene]](https://englogs.com/wp-content/uploads/2022/09/Gas-welding-machine-parts-and-functions-1-300x180.jpg)