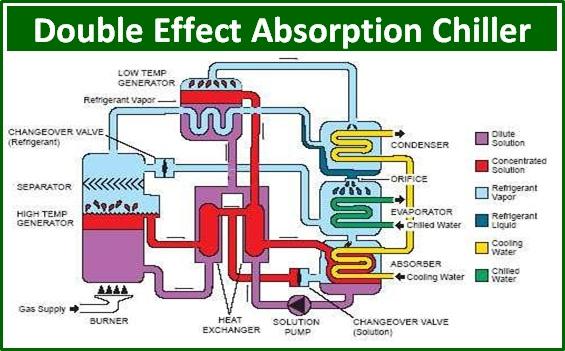

Double effect absorption chiller is an improvement in single effect lithium bromide chiller (read here all about Single effect absorption chiller ) . Double effect water chillers have more coefficient of performance and enhanced utilization of input energy.Basic working principle of these dual effect absorption chillers remains same as single effect but with addition of some components to vapor absorption cycle. Absorption cooling is enhanced using the system energy which would have been otherwise wasted as in case of single effect industrial chiller.In order to produce chilled water in these double effect chillers,water remains as a refrigerant and lithium bromide as absorbent in these HVAC water chillers. As compared to single effect absorption chillers,double effect vapor absorption chiller has an additional heat exchanger and generator/concentrator.

Basics of Double effect Absorption Chiller Operation

HP Generator Process in Double effect Absorption Chiller Operation

In double effect absorption chiller,both in direct and indirect fired chiller operation, weak solution from the absorber is pumped into the HP generator through LT, condensate and HT heat exchangers. It is heated by operating steam and concentrated to the intermediate solution, and high temperature refrigerant vapor is produced.Instead of steam ,hot exhaust gases or waste heat may also be used as in case of direct fired absorption chillers.

LP Generator and HT exchanger Process in Double effect Absorption Chiller Operation

In next step of chiller operation,Intermediate solution enters LP generator through HT heat exchanger in exchanging heat with weak solution which is passed through the tubes. Intermediate solution in LP generator is heated by the refrigerant vapor from HP generator, concentrated to the strong solution, releasing refrigerant vapor at the same time.

LT Heat exchanger Process in Double effect Absorption Chiller Operation

The strong solution passes through the outside tube space of LT heat exchanger, enters absorber, transmitting heat to the weak solution from absorber. In absorber the strong solution absorbs refrigerant vapor again.

Condenser Process in Double effect Absorption Chiller Operation

Refrigerant vapor from HP generator is condensed in LP generator to form condensate, which enters condenser through throttle. Refrigerant vapor formed in the LP generator flows to the condenser to form condensate also.

Evaporator ,Refrigerant Pump and Absorber Process in Double effect Absorption Chiller Operation

At normal temperature and pressure water boils at 212oF but as pressure is lowered sufficiently below atmospheric pressure then boiling temperature is also decreased .Same thing is used in evaporator of absorption chillers(single and double effect ).

These two parts of refrigerant condensate flows into the flash chamber through U pipe. A part of refrigerant water is flashed to form vapor, which flows into the re-absorption chamber at the bottom of absorber, while another part of refrigerant water is cooled, and enters evaporator refrigerant pan. Refrigerant from evaporator refrigerant pan is pumped over the evaporator tubes for the refrigeration effect, and evaporates to form vapor by absorbing heat of chilled water flowing through tubes.

Produced refrigerant vapor enters absorber, and absorbed by strong solution in the absorber. Chilled water is cooled and return to the HVAC system of customer. Strong solution is diluted by absorbing refrigerant vapor in absorber and absorbing flashed refrigerant vapor in the re-absorption chamber.

Solution Pump in Double effect Absorption Chiller Operation

Weak solution is then transferred by solution pump to HP and LP generator for concentration. Heat generated is carried to atmosphere by cooling water. This process is continued, and refrigeration effect is repeated.

![Read more about the article HVAC Duct Friction Loss Spreadsheet Calculator Free Download [xlsx]](https://englogs.com/wp-content/uploads/2022/12/HVAC-Duct-Friction-Loss-Excel-Calculator-2-300x169.jpg)