What Is A Thermal Power Plant?

A thermal power station is a power station in which heat energy is converted to electricity. Typically, water is heated into steam, which is used to drive an electrical generator. After it passes through the turbine the steam is condensed in a steam condenser and recycled to where it was heated.

This is known as a Rankine cycle. The greatest variation in the design of thermal power stations is due to the different heat sources: fossil fuel, nuclear energy, solar energy, biofuels, and waste incineration are all used.

Certain thermal power stations are also designed to produce heat for industrial purposes, for district heating, or desalination of water, in addition to generating electrical power.

How Does Thermal Power Plant Work:

In thermal power plants, the heat energy obtained from the combustion of solid fuel (mostly coal) is used to convert water into steam, this steam is at high pressure and temperature.

This steam is used to rotate the turbine blade turbine shaft is connected to the generator. The generator converts the kinetic energy of the turbine impeller into electric energy.

A thermal Power Plant consists of a whole set of steps in series for producing electricity.

The fuel is transported from mines via trains to the fuel storage facility in a power plant. The fuel transported to the plant is generally bigger in particle size and before it is fed to the boiler furnace it is broken down into smaller pieces using crushers. The fuel is then fed to the boiler generating a large amount of combustion heat.

On the other hand, treated water free from impurities and air is fed to the boiler drum where the combustion heat from the fuel is transferred to water to convert it into high pressure and temperature steam.

Generally, flue gases from the boiler exhaust are at high temperature and if this heat is not utilized will lead to a large number of losses resulting in reduced boiler efficiencies.

So generally, this waste heat is recovered by heating either air required for combustion or preheat water before sending it into a boiler.

Flue gases are then allowed to pass through a dust collector or a bag filter to arrest dust particles so as to prevent air pollution before sending it to the atmosphere through a chimney.

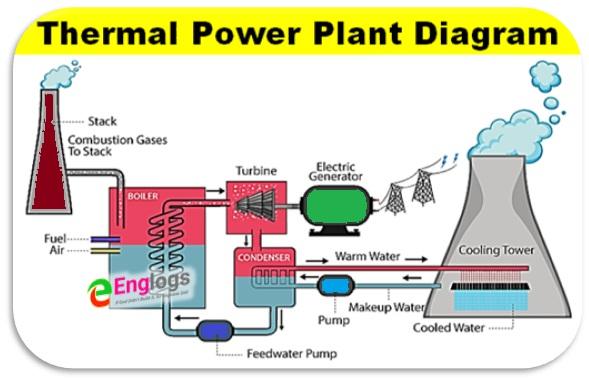

Thermal Power Plant Diagram:

Components Of Thermal Power Plant

Fuel Storage And Handling Plant:

The most essential part of any power plant is to store the fuel safely in an appropriate amount so that the plant can run smoothly on normal days as well as when the supply of fuel from mines is improper. So, a fuel storage facility is defined in a plant to store an adequate amount of fuel.

In a thermal power plant process, the first step in process of power generation is that the fuel is brought to the breaker house with the help of a belt conveyor, here light dust is separated with the help of a rotary machine through the action of gravity.

It further goes to the crusher where it is crushed to a size of about 50mm.

Water Treatment Plant:

In thermal power, plant water is used in large quantity this water is converted into steam and used to rotate the turbine so this water and steam come into direct contact with the boiler, boiler tubes, boiler accessories, and turbine blades.

Normal water is taken from the river, well contains a lot of dirt, suspended particulate matter (SPM), dissolved minerals, and dissolved gases such as air, etc. If the water fed to the boiler is not treated then it will reduce the life and efficiency of equipment by corroding the surfaces and scaling of equipment which may lead to overheating of pressure parts and explosions.

Suspended matter from the water is removed by adding alum into the water tank through gravity separation. The addition of alum coagulates the suspended particles and due to an increase in the density, it settles at the bottom of the tank through gravity.

After gravity separation, water softening is done by the ion exchange process. As the hardness comes through the carbonates and bicarbonates of sodium and magnesium, these salts are removed from the water anion exchange and cation exchange process.

Water also contains dissolved oxygen and this leads to corrosion and fouling of boiler tubes and surfaces when it comes in their contact. So, removing dissolved oxygen from water is done by adding oxygen scavengers and by using a Deaerator tank.

The Deaerator tank also acts as a feedwater tank to store the feed water. On heating feed water in a deaerator tank decreases the solubility of air in water, thereby removing the dissolved air from the water.

Steam Boiler:

A boiler is a pressure vessel that is used to generate high-pressure steam at a saturated temperature. At this high pressure and temperature generally, bi-drum water tube boilers are used.

The Water-tube boiler consists of a furnace enclosed by the water tubes membrane. The crushed fuel from the crushers is fed into the boiler furnace over the grate.

The hot air from the Forced Draft (FD) fan is mixed with the crushed fuel causing combustion of fuel.

Combustion of fuel generates a lot of radiation heat which is transferred to water in the membrane tubes. Flue gases generated during combustion travel at high velocity across the convection bank of tubes thereby heating water through convection heat transfer. Hot water is sent to a boiler drum at high pressure through the feed-water pump.

The boiler tubes which are in contact with low temperature acts as downcomers to circulate the water while the tubes which are in contact with high temperature acts as risers to carry steam.

Turbine:

A turbine is a mechanical device that converts the kinetic and pressure energy of steam into useful work. From the superheater steam goes to the turbine where it expands and loses its kinetic and pressure energy and rotates the turbine blade which in turn rotates the turbine shaft connected to its blades.

The shaft then rotates the generator which converts this kinetic energy into electrical energy.

Advantages Of Thermal Power Plants:

Making Energy from Thermal Power plants is easy

The fuel used (coal) is cheap

Thermal Power Plant can be set up anywhere near fuel and water supply

It requires less space as compared to the hydroelectric power station

Disadvantages Of Thermal Power Plants:

Thermal Power Plants use Fossil Fuels to generate electricity, and these fossil fuels causes pollution

A large water source is required to convert water into steam

It has low overall efficiency

Its maintenance cost is high