Phased array is widely used for nondestructive testing (NDT) in several industrial sectors, such as construction, pipelines, and power generation. This method is an advanced NDT method that is used to detect discontinuities i.e. cracks or flaws and thereby determine component quality.

Principle of Operation:

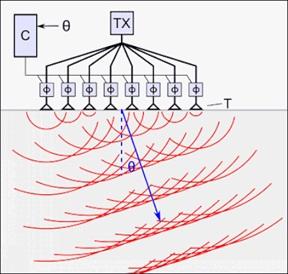

The PA probe consists of many small ultrasonic transducers, each of which can be pulsed independently. By varying the timing, for instance by making the pulse from each transducer progressively delayed going up the line, a pattern of constructive interference is set up that results in radiating a quasi-plane ultrasonic beam at a set angle depending on the progressive time delay. In other words, by changing the progressive time delay the beam can be steered electronically. It can be swept like a search-light through the tissue or object being examined, and the data from multiple beams are put together to make a visual image showing a slice through the object.

Use in industry:

Phased array is widely used for nondestructive testing (NDT) in several industrial sectors, such as construction, pipelines, and power generation. This method is an advanced NDT method that is used to detect discontinuities i.e. cracks or flaws and thereby determine component quality. Due to the possibility to control parameters such as beam angle and focal distance, this method is very efficient regarding the defect detection and speed of testing. Apart from detecting flaws in components, phased array can also be used for wall thickness measurements in conjunction with corrosion testing

Phased array can be used for the following industrial purposes:

- Inspection of welds

- Thickness measurements

- Corrosion inspection

- PAUT Validation/Demonstration Blocks[5]

- Rolling stock inspection (wheels and axles)

- PAUT & TOFD Standard Calibration Blocks

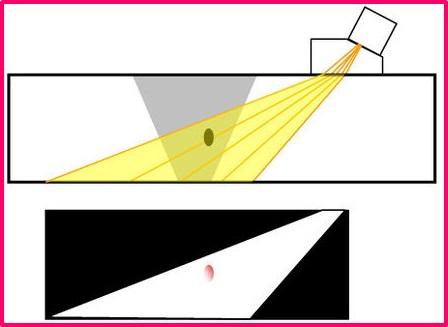

Weld examination by phased array. TOP: The phased array probe emits a series of beams to flood the weld with sound. BOTTOM: The flaw in the weld appears as a red indication on the instrument screen.

At a construction site, a technician tests a pipeline weld for defects using an ultrasonic phased array instrument. The scanner, which consists of a frame with magnetic wheels, holds the probe in contact with the pipe by a spring. The wet area is the ultrasonic couplant that allows the sound to pass into the pipe wall.

Standards:

European Committee for Standardization (CEN)

- prEN 16018, Non destructive testing – Terminology – Terms used in ultrasonic testing with phased arrays

- ISO/WD 13588, Non-destructive testing of welds – Ultrasonic testing – Use of (semi-) automated phased array technology

Code:

ASME Boiler and Pressure Vessel Code. American Society Of Mechanical Engineers, 2013. Section V — Nondestructive Examination. [See Article 4 — Ultrasonic Examination Methods for Welds. Para E-474 UT-Phased Array Technique]

References: Wikipedia, Thankyou