MAJOR VALVE STANDARDS PETROCHEMICAL AND REFINING INDUSTRY

API 594 Check Valves – Tilt, Swing & Dual Flap, Flanged, Lug, Wafer & Buttweld Ends

This standard covers the design, materials, face-to-face dimensions, pressure-temperature ratings, inspections, examination, and testing requirements for two types of swing, dual plate & tilt check valves.

API 600 Cast Steel Gate Valves – Flanged & Buttwelding Ends

API 600 is the main steel gate valve specification. Valve design and construction criteria are specified, as well as materials and trim designations. An appendix covers information pertaining to pressure seal valves. ISO Standard 10434 is essentially the same as API 600, re-produced in the ISO format.

API 602 Compact Steel Gate Valves – Flanged, Threaded, Welding and Extended-Body Ends

API 602 is for 100 NB (4”) & smaller forged steel gates valve specification. Valve design and construction criteria are specified, as well as materials and trim designations. This standard includes requirements for bellows seal gate valves. In 150, 300 and 600 class API 602 requires a heavier wall than ANSI B16.34

API 603 Cast Gate Valves Corrosion – Resistant, Flanged-End

API 603 covers light walled gate valves in sizes NPS 15mm to 600mm (1/2” through 24”), in classes 150, 300 & 600. These valves are used in applications where a thicker API 600 casting is not needed. However, the wall thickness normally dual conforms to ANSI B16.34 wall.

API 623 Cast Globe Valves – Flanged & Buttweld Ends

This standard covers the requirements for globe valve used in the downstream refinery industry for oil and gas. Specifically, the standard specifies a thicker walled construction and a guided disc as well as requiring low emission performance when compared against ASME B16.34 valves.

API 608 Steel Ball Valves – Flanged and Buttweld Ends

Typically used for floating ball valves, API 608 is the purchase specification for class 150, 300, 600 and 800 class steel ball valves. Valves design and construction criteria are detailed. Trunnion mounted pipeline ball valves are manufactured to API 6D but API 608 is also allowable in refineries up to 500 NB (20”).

API 609 Butterfly Valves – Lug-Type and Wafer-Type

API 609 is a specification for butterfly valves with lug-type and wafer-type configurations designed for installation between ANSI B16 flanges, 150 to 1500 class.

API 598 Valve Inspection & Testing

API 598 covers the testing and inspection requirements for check, gate, globe, ball, plug & butterfly valves. Steel valve pressure ratings in ASME/ANSI B16.34 are required to determine API 598 test pressure for steel valves.

API 6D Specification for Pipeline Valves – Gate, Plug, Ball and Check Valves

Specification for pipeline valves (gate, ball, plug, and check valves) API 6D is the primary standard for valves used in main line pipeline service, including gate, ball, plug and check valves. Occasionally refinery and petrochemical purchasers will reference the more stringent testing requirements of API 6D. Similarly ball valves manufactured to API 608 may be specified as tested to API 6D.

ASME/ANSI B16.34 Steel Valves – Flanged & Buttwelding Ends

ASME B16.34 is the standard in which steel valve pressure/temperature ratings are specified. It also offers additional valve specification data including non-destructive examination procedures for upgrading valves for special class service. Gate valves manufactured under B16.34 wall thickness minimums may not meet the minimum wall thickness required of API 602 (forged valves) for class 150, 300 and 600.

ASME/ANSI B16.10 Face-to-Face Dimensions of Ferrous Valves

B16.10 specifies the face-to-face dimensions of all flanged and buttweld end valves. Screwed and socketweld end valve face-to-face dimensions are not included in this standard.

MSS SP-55 Quality Standard for Steel Castings for Valves, Flanges and Fittings and other Piping Components

MSS SP-55 outlines the visual inspection criteria for castings (& forgings). This specification is listed as part of the procedure under API 598.

NACE MR-0175 Standard for Sour Service

Standard material requirements for sulfide stress cracking resistant metallic materials for oilfield equipment MR-0175 is the ‘standard’ for materials used in ‘sour’ environments such as found in piping systems in many refineries. It lists materials, mechanical properties and heat treatments for metals used in hydrogen sulfide bearing hydrocarbon service.

BS 1873 Specification for Steel Globe Valves

Now redundant, only used for light industrial valves (1975). For oil & gas and refinery use refer to API 623. BS 1873 outlines specifications for flanged and buttweld end globe and stop check valves for petroleum petrochemical and allied industries.

BS 1868 Specification for Steel Check Valves

Now redundant (1975). BS 1868 outlines specifications for flanged and buttweld end check valves, API 594 is now expanded to include swing and tilt check valves for upstream & refinery check valves. API 6D is used for ‘pipeline’ check valves, API 594 also require check valves to conform to the requirements of ASME B16.34

ANSI/ASME STEEL GATE, GLOBE & CHECK VALVES

Cast Gate Valves – API 600/API 603

For users of cast gate valves, API 600 is the key standard. It details all design material criteria. API 600 also lists important dimensions such as stem diameter minimums, wall thickness and stuffing box size. Another important gate valve standard is ASME B16.34. This standard outlines requirements on valves constructed to ASME boiler code pressure temperature ratings. One important area in which API 600 differs from ANSI B16.34 is minimum wall thickness. API 600 requires a heavier wall for a given pressure rating than does ASME B16.34. API 603 is optionally used for 150# and 300# stainless steel valves and allows a lighter wall thickness than API 600 and is used for corrosion resistant valves. API 603 wall thickness normally dual conforms to ASME B16.34.

Cast Check Valves – API 594 & API 6D

Check valves are manufactured to API 6D (full opening pipeline swing check valves and piston check valves) and API 594 swing, tilt & dual plate check valves. Valves manufactured API 594 & API 6D stocked by Global Supply Line also conform to ANSI B16.34 wall thickness and other design criteria. API 594 meets & surpasses the requirements of BS 1868. API 594 also ensures a heavier wall thickness than API 594. BS 1868 is redundant (not updated since 1975) but is still used for light industrial swing check valves. For oil & gas and refinery use API 594 is now specified for swing and tilt check valves. Piston check valves can be manufactured to API 6D or ASME B16.34 dual conforming to BS 1873, with wall thickness in accordance with API 594.

Cast Globe Valves – API 623

Globe Valves are manufactured to API 623. They are also made in accordance with ASME B16.34 (API 623 requires a heavier wall thickness than B16.34). BS1868 is redundant (not updated since 1975) but may still be used for light industrial valves. API 623 meets and surpasses the requirements of BS 1873.

Forged Gate, Globe & Check Valves – API 602

Small forged carbon steel gate, globe & check valves in 150#, 300#, 600#, 800# & 1500# class valves are covered by API 602. ANSI 150 to 2500 forged, check and globe valves can also be manufactured to ISO 15761. BS 5352 is now obsolete and covered by ISO 15761 which also incorporates API 602 and covers up to 2500 class. Forged check, gate & globe valves in 2500# are also manufactured to ANSI B16.34. API 602 specification covers the same details for small forged valves that API 600 does for larger valves.

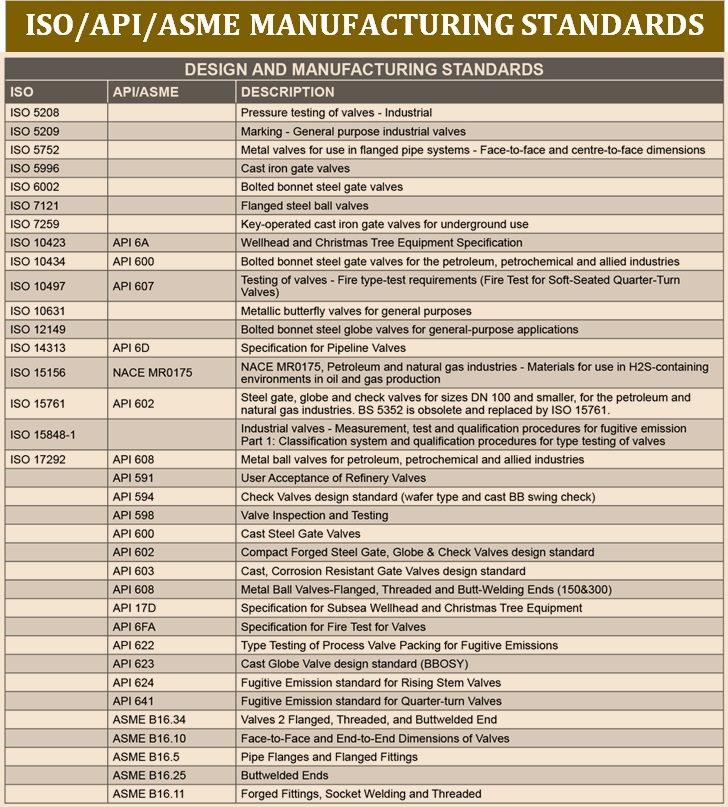

ISO/API/ASME MANUFACTURING STANDARDS

ISO has been part of an international effort to standardise the products for petroleum and natural gas industries. The following table shows API and ASME equivalents which ISO has so far mirrored and aligned with. Global Supply Line supplies and stocks valves to the following standards:

COMMON VALVE ABBREVIATIONS

COMMON VALVE TYPES & RELATED TEST STANDARDS

![Read more about the article Valve Basic Interview Questions and Answers [QC Notes]](https://englogs.com/wp-content/uploads/2022/10/Valve-Basic-Aramco-CBT-Exam-Questions-Answers-300x187.jpg)