Boiler Mountings

Boiler mountings are those essential fittings, devices, and controls that are directly attached to the boiler itself Boiler Drum, or Shell. They are primarily responsible for the safe and efficient operation of the boiler by ensuring its integrity and providing necessary safeguards. Common boiler mountings include:

- Safety Valve

- Water Level Indicator

- Pressure Gauge

- Steam Stop Valve

- Fusible Plug

- Blowdown Valve /Blow-off Cock

- Feed Check Valve

1. Safety Valve

Boiler safety valves are the guardians of boiler pressure. They prevent excessive pressure buildup by releasing steam when the pressure exceeds a predetermined limit. This crucial component ensures the safety of both the boiler and the personnel operating it. Thus it prevents the boiler from overpressurizing, which can lead to catastrophic failures.

2. Water Level Indicator

This device provides a visual indication of the water level inside the boiler. It typically consists of a gauge glass and a set of valves water cock and steam cock to monitor and maintain the correct water level, preventing damage due to low water or carryover of water into the steam. They come in various types, such as glass gauges and magnetic indicators, providing an accurate visual representation of the water level. Maintaining the correct water level is crucial to prevent overheating and damage to the boiler.

3. Pressure Gauge

Pressure gauges are like the eyes of the boiler. They provide real-time information about the boiler’s internal pressure. Operators rely on pressure gauges to ensure the boiler operates within safe pressure limits. Pressure gauges used as boiler mountings are typically designed to withstand the high temperatures and pressures commonly found in boiler systems. They are usually calibrated to provide pressure readings in units such as pounds per square inch (psi) or bars, depending on regional standards and the specific application. The most commonly, the Bourdon pressure gauge is used.

4. Steam Stop Valve

Steam stop valves control the flow of steam from the boiler to the steam distribution system. The steam stop valve is located on the highest part of the steam space. It regulates the steam supply to use. They can be manually operated and are essential for isolating the boiler from the rest of the system during maintenance or emergencies.

5. Fusible Plug

The fusible plug is a safety device installed in the boiler’s combustion chamber. It contains a fusible alloy that melts at a specific temperature, allowing steam to escape in case the water level in the boiler drops too low, preventing overheating and damage. During the normal boiler operation, the fusible plug is covered by water and its temperature does not rise to its melting state. But when the water level falls too low in the boiler, it uncovers the fusible plug. The furnace gases heat up the plug and fusible metal of plug melts, the inner plug falls down The water and steam then rush through the hole and extinguish the fire before any major damage occurs to the boiler due to overheating.

6. Blowdown Valve /Blow-off Cock

A blowdown valve, also known as a blow-off cock, is an important component in a steam boiler system. Its primary purpose is to discharge or “blow down” a portion of the boiler water to remove impurities, dissolved solids, and other contaminants that can accumulate over time. Blowdown valves can come in different types, including quick-opening valves and slow-opening valves. Quick-opening valves. Regular blowdown helps maintain the quality of the boiler water, ensuring that it remains within acceptable limits for factors like total dissolved solids (TDS), alkalinity, and pH. Proper water quality is essential for efficient and safe boiler operation. Boiler Blowdown calculations.

7. Feed Check Valve

The primary function of a feed check valve is to prevent the backflow of water from the boiler into the feedwater supply line. This is crucial for maintaining the separation between the high-pressure boiler water and the lower-pressure feedwater, preventing contamination and ensuring that only treated and controlled feedwater enters the boiler. It also prevents the return of feed water from the boiler if the Boiler feed water pump fails.

Boiler Accessories

Boiler accessories are additional components or attachments that enhance the performance and efficiency of the boiler system. They are not directly connected to the boiler’s safety /nor directly attached to the boiler shell but provide auxiliary functions to improve overall boiler operation and efficiency. Common boiler accessories include:

8. Economizer

An economizer is a vital boiler accessory designed to improve the overall energy efficiency of a steam boiler system. Its primary function is to recover heat from the flue gases exiting the boiler and use that heat to preheat the incoming feedwater before it enters the boiler. This process significantly reduces fuel consumption, lowers operating costs, and helps mitigate environmental impact.

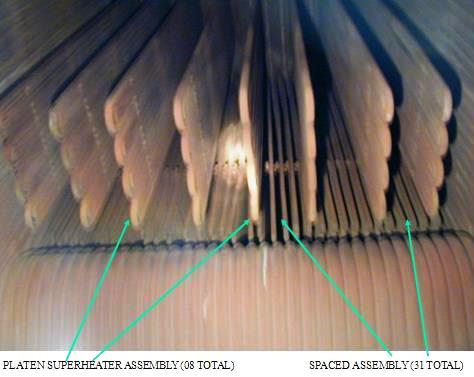

9. Superheater

A superheater is a crucial component in a steam boiler system, specifically in the power generation and industrial processes where steam is used as a source of energy or for various applications. Its primary function is to increase the temperature of the steam generated by the boiler beyond its saturation point, turning it into superheated steam. Superheated steam is steam that has been heated to a temperature higher than its boiling point at a given pressure, which offers several advantages and applications.

10. Air Preheater

An air preheater is an important boiler accessory used in various industrial processes, particularly in steam boiler systems and power plants. Its primary function is to heat the incoming combustion air before it enters the boiler’s combustion chamber. This preheating process improves the overall energy efficiency of the boiler and has several significant benefits: Increased Efficiency, Faster Start-up, and burn of low-grade fuel.

11. Feed Pump

Feed pumps are essential for maintaining a steady supply of water to the boiler. They ensure that the boiler always has enough water to operate efficiently. A boiler feed pump is a critical component of a steam boiler system, especially in larger industrial and power plant boilers. Its primary function is to deliver a consistent and pressurized supply of water (feedwater) to the boiler to maintain the required water level and pressure within the boiler. Here are the key aspects and functions of a boiler feed pump.

12. Blowdown Valve

Blowdown valves are used to remove impurities and sediments from the boiler water. This process helps maintain water quality and prevents the buildup of harmful substances inside the boiler.

Boiler Mountings and Accessories: Key Differences

Now that we have explored the individual components let’s highlight the key differences between Boiler Mountings and Boiler Accessories:

13. Location

- Boiler Mountings: These components are directly attached to the boiler shell.

- Boiler Accessories: They are not directly attached to the boiler shell but are connected to various parts of the boiler system.

14. Primary Function

- Boiler Mountings: They are primarily responsible for ensuring the safety of the boiler and its operation.

- Boiler Accessories: These enhance the boiler’s efficiency and performance.

15. Mounting Point

- Boiler Mountings: Attached at specific mounting points on the boiler.

- Boiler Accessories: Connected at various points in the boiler system to optimize its functionality.

16. Safety Role

- Boiler Mountings: They play a crucial safety role by preventing accidents due to excessive pressure, low water levels, and other potential hazards.

- Boiler Accessories: While they contribute to efficiency, their primary role is not safety-related.

17. Direct vs. Indirect Impact

- Boiler Mountings: Have a direct impact on the boiler’s safety and immediate operation.

- Boiler Accessories: Influence the boiler’s performance but do not have an immediate impact on safety.

18. Examples

- Boiler Mountings: Safety valve, water level indicator, pressure gauge, steam stop valve, fusible plug.

- Boiler Accessories: Economizer, superheater, air preheater, feed pump, blowdown valve.

FAQs (Frequently Asked Questions)

What is the purpose of a safety valve in boiler mountings?

A safety valve in boiler mountings is designed to release steam when the boiler’s pressure exceeds safe limits. It prevents potential accidents caused by overpressure.

Why is the water level indicator essential in boiler mountings?

The water level indicator in boiler mountings provides a visual representation of the water level inside the boiler. It helps operators ensure the correct water level is maintained to prevent overheating and damage.

How do boiler accessories like economizers improve efficiency?

Economizers recover heat from flue gases, preheating the feedwater. This reduces fuel consumption, making the boiler more energy-efficient.

What role does a superheater play in boiler accessories?

A superheater increases the temperature of steam produced by the boiler, making it suitable for various industrial applications, including power generation.

Why are air preheaters used in boilers?

Air preheaters heat the combustion air before it enters the boiler, improving fuel combustion efficiency and reducing energy wastage.

What is the purpose of a blowdown valve in boiler accessories?

A blowdown valve is used to remove impurities and sediments from the boiler water, maintaining water quality and preventing harmful buildup.

Conclusion

In this comprehensive guide, we’ve explored the world of Boiler Mountings and Boiler Accessories, understanding their distinct roles and differences. Boiler mountings are the safety guardians of boilers, ensuring their safe operation, while boiler accessories enhance efficiency and performance. Both components are essential for the smooth functioning of steam boilers, contributing to their reliability and longevity.

Understanding these vital elements is crucial for anyone involved in the operation and maintenance of boilers. By recognizing their roles and differences, operators can ensure the safe and efficient operation of these essential industrial machines.