Water chillers are backbone of HVAC cooling systems.Water chiller is a refrigeration machine which produces chilled water ( Approx 7 Degree C ~ 12 Degree C).The primary function of a chiller is to lower the temperature of water to such value such that it can be used for producing cooling effect in integration with other HVAC components. A water chiller is just like a other refrigerator machine but instead of keeping your food cool or making ice,it produces chilled water.The output of chiller is a water at lower temperature usually around about 10 o C depending upon the Chiller design.

HVAC water chillers play vital role in any HVAC systems along with other basic components. Chillers have got much attention in recent years for its new designs and performance improvement in existing designs. New designs have resulted in hvac chiller with better efficiency and less operation and maintenance costs. Another desirable features is energy saving and precise load or capacity control for new chillers. We see the chillers with above features in market but as engineering professionals we hope to see more with design improvements with less O & M cost. It is essential part of HVACsystem to have a chiller. Chiller manufacturers have also expanded their production as well design capabilities to cater to the diversified demands of HVAC chillers.

HVAC Chiller Basics

Working Principle of Vapor Compression Chiller

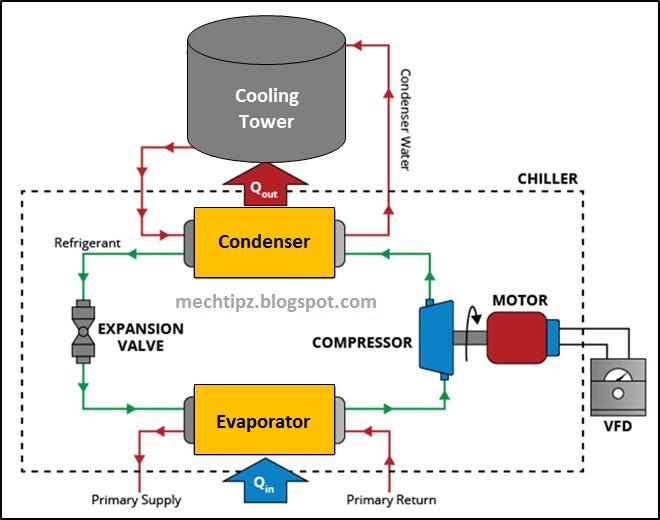

An HVAC chiller works on vapor compression or vapor absorption cycle.In vapor compression cycle, refrigerant circulates in evaporator ,compressor, condenser and expansion valve of a chiller. A thermodynamic process occurs in each of above chillers.Theoretical working of Vapor compression or compression chillers is explained below.

Heat addition to refrigerant in evaporator ( 1-2):

Refrigerant gets vaporized by taking heat from chilled water in evaporator thus serving its prime purpose. Refrigerant comes out of evaporator as vapors but on other side chilled water is produced. Thus heat is added to refrigerant at constant pressure but is extracted from chilled water. Both refrigerant and chilled water don’t get mixed and are separated by some solid wall in between them in evaporator like shell and tube design.

Compression of refrigerant vapors in compressor (2 – 3 ):

Refrigerant vapors come out of evaporator and then compressed by chiller compressor to high pressure and temperature. Compressor requires energy input for its working and hence electric energy is supplied to it.

Heat rejection by refrigerant in condenser ( 3 – 4 ) :

Similar to evaporator ,but reverse is happening here. Refrigerant rejects its heat to outside cooling liquid or air .In this way, refrigerant gets condensed and outside media is heated. outside media e.g. cooling water may be cooled by cooling tower and recycled again into condenser.

Expansion of refrigerant in expansion valve ( 4 -1 ) :

Refrigerant in condensed form coming out of condenser is expanded in expansion valve and its pressure and temperature is reduced to level of evaporator so that above cycle is repeated again.

In above four components of hvac chiller ,evaporator is the part where we get chilled water after exchanging heat with refrigerant .

![Read more about the article [pdf] HVAC Ducting Principles and Fundamentals Free Download](https://englogs.com/wp-content/uploads/2022/12/HVAC-Ducting-Principles-and-Fundamentals-1-300x175.jpg)